What is Rum?

Rum is a distilled alcoholic beverage made from fermented sugarcane juice, sugarcane syrup, sugarcane molasses or any other sugarcane by-product. Its exact origin is debated, but it is widely believed to have originated in the Caribbean during the 17th century. It is thought to have been first distilled in the Caribbean islands, particularly in Barbados, which has a long history of sugar cane cultivation.

Read More article – 5 fantastic Scotch-based drinks

The Rum Production Process

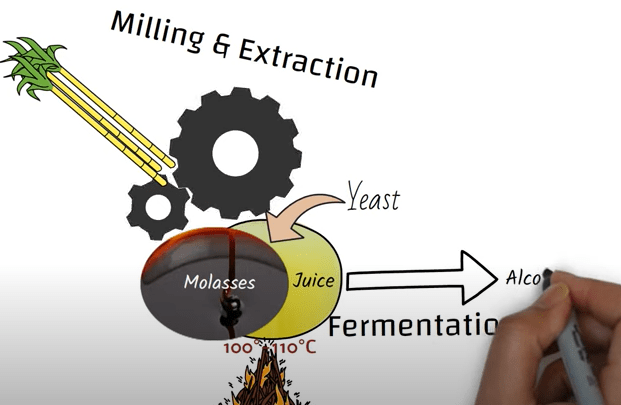

Milling and Extraction:

- Crushing: where sugar cane stalks are crushed in a mill to extract the juice and filter it.

- Filtering: This juice contains sugar, water, and various other compounds that contribute to the flavour of the rum.

- Types of Juice Usage:

Direct Use: We can directly use this juice to produce Rum. This type of rum where we use fresh sugarcane juice, is called Rhum Agricole. And this style of rum is particularly associated with Martinique (a Caribbean island). Rhum is a French word for Rum.

Molasses Production: we can also heat this filtered sugarcane juice around 100 to 110 degree Celsius. At this temperature water is evaporated off, leaving behind thick syrup known as “sugar cane molasses.

Fermentation:

- Adding Yeast: Y Now in this sugarcane juice or molasses, Yeast is added to start the Fermentation process.

- Process: In this process yeast converts sugars into alcohol and carbon dioxide. Fermentation typically takes several days.

- Outcome: Now this carbon di oxide escapes into air and we are left with this fermented alcohol also known as “wash” or “beer” with which typically possesses alcohol content roughly between 5-15%. After fermentation in the wash.

Distillation:

- Heating: In which we heat this wash around 75-80 degree Celsius. Alcohol evaporates at lower temperature as compared to water, and this evaporated alcohol vapours are passed through pipe and at the other end it is cooled down, to covert this vapours back into liquid form.

- Proofing: Hence we get this distilled alcoholic beverage or spirit with more alcohol percentage. This is actually our RUM. Now, we can also repeat this process to increase the alcoholic percentage. As per USA standards, we should repeat this distillation process till we get 190 proof or we can say 85% alcoholic concentrated liquid or ABV.

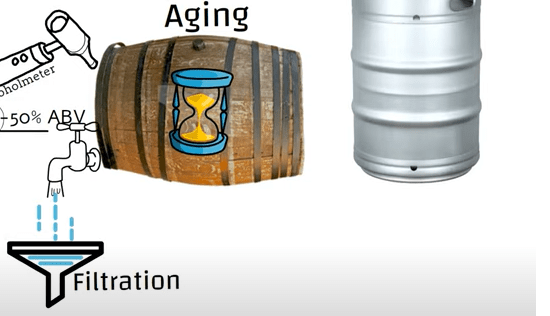

Aging (Optional):

- Barrels: Wooden barrels are preferred to develop flavor and character. The type of barrel used and the duration of aging can significantly influence the final product.

- Color: A When aged in oak barrels the rum becomes dark, versus being aged in stainless steel tanks where it remains virtually colorless.

Post-Aging Processing:

- Alcohol Adjustment: Aging is optional, not mandatory. You may also skip this step. After aging, we check for alcohol percentage, normally, the alcohol percentage (ABV) is kept in the range of 40 to 50 percent. As per USA standards, the minimum alcoholic percentage is 40 percent. maximum is not mentioned. If alcohol percentage is more than the desired level that we add water to bring it down to the desired level.

- Filtration: It undergo filtration to remove any impurities and achieve clarity.

- Bottling: Finally, the rum is bottled, labelled, and prepared for distribution and sale.

How to Drink Rum ?

Well you can drink it in many different ways. Below mention

- Neat: Drinking rum straight without any additives. Similar to the drink, it can be drunk neat.

- On the Rocks: Served with ice.

- Mixed: Combined with cola, orange juice, or other mixers.

- Cocktails: here are also many cocktails in which rum is used. For example: Pina colada, daiquiri, mai tai, Bahama mama, mojito etc .

Pingback: The Yamazaki 12: Japanese Single Malt Review -